Submersible motor winding wire

1. [0001] The utility model in this paper belongs to the field of submersible motors, and secondly relates to the power cable lead T6670 of a submersible motor winding. 2. [0002] In view of the fact that submersible motors are used in water, X35KB96SG insulating materials need to be able to have good electrical insulation properties from water for a long time. In addition, they can be sealed and isolated from water and non-electric contact. 3. Especially in the 100 more than 20 years since submersible motors were put into use, it is counted that about 50% of motor operation faults are at least electrical faults. However, the secondary occurrence of electrical faults is insulation breakdown if the insulation resistance is low. 4. The vast majority of damaged parts that cause faults are the connection parts between windings and lead-out cables. How can we design this novel approach to make the breakdown problem never occur, thus solving these long-standing problems that have affected the reliability of motors for many years and becoming a research topic for technicians in this field.

2023-05-31

Matters needing attention in maintenance of large flow submersible motor

Oil injection method: Hoist the motor or pad it flat and upright (pay attention to prevent dumping and hurting people). First tighten the oil pressure spring to a tight state, repair the high-pressure submersible motor, then open the oil plug on the top of the motor, and slowly inject oil into the machine. Tighten the oil plug after filling the oil, remove the screw to loosen the spring. At this time, oil pressure is generated in the machine. In order to eliminate the residual gas in the machine, loosen the oil plug to exhaust naturally. When there is no air discharge sound, the exhaust is completed when the oil spills. Add oil to large flow submersible motor; 150A motor h 2 150±5lllm,200 and 250B motor h: 110±5mm, see appendix d.

2023-05-31

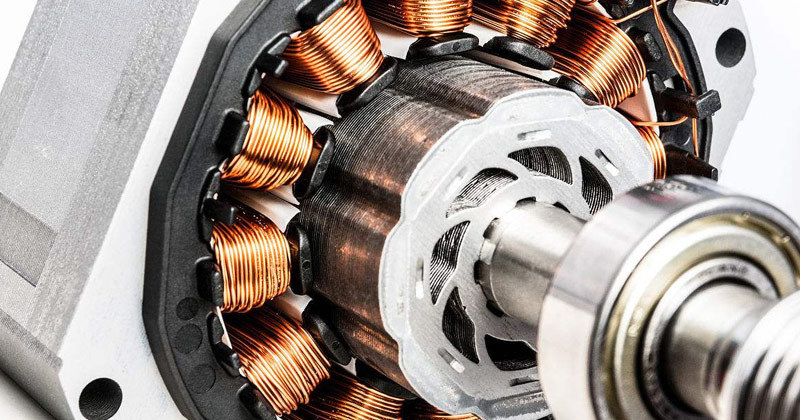

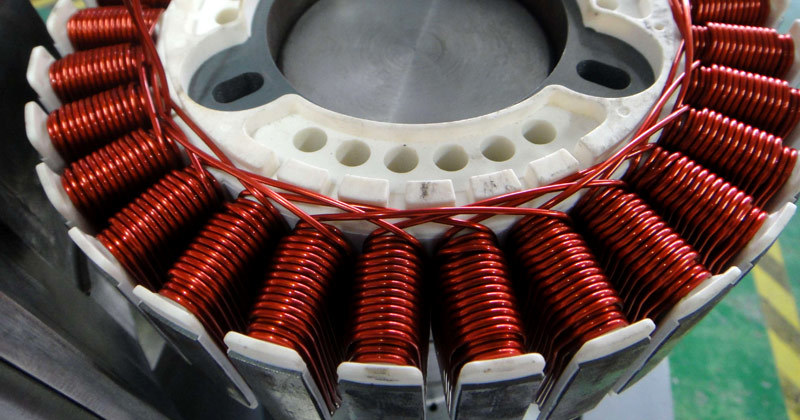

Submersible motor for three-phase well 4OS22T

1. Three-phase asynchronous motor for motor operation. 2. The speed of the rotor of the three-phase asynchronous motor is lower than the speed of the rotating magnetic field. There will be relative movement between the rotor winding and the magnetic field. However, electromotive force and current are generated, which interact with the magnetic field to generate electromagnetic torque and realize energy conversion. Compared with its single-phase asynchronous motor, three-phase asynchronous motor has good running performance, which can save a variety of materials. 4, in strict accordance with the different rotor structure, three-phase asynchronous motor can be divided into cage type such as winding type five. 5. Cage rotor asynchronous motors have simple structure, reliable operation, light weight and low price, and have been widely used. The primary disadvantage of the latter is difficulty in speed regulation. 6. The stator of the rotor of the winding old three-phase asynchronous motor is not only set up as a three-phase winding, but also uses slip rings and brushes to connect with non-internal and external rheostats.

2023-05-31

Does the oil filter need to be replaced when servicing the oil?

The service life of a vehicle usually depends on its key component-the engine. The engine is like the "heart" part of the human body, and a good filter is equivalent to the "kidney" part of the body to expel toxins. During the operation of the diesel engine, the impurities deposited in the fuel system and the dust suspended in the air will pollute the diesel and affect the quality of the diesel itself. Therefore, the fuel filter on the car is essential. Most diesel engines use a high-pressure common rail fuel system. In order to ensure high-pressure injection, the system needs to accurately control the injection pressure, injection flow and injection time. Its accessories are very exquisite workmanship, so there are higher requirements for diesel quality, especially the control of diesel cleanliness, which is quite strict. If there is unfiltered moisture or impurities in the diesel fuel, long-term use will cause damage to the injector high-pressure pump. Impurities that are not filtered will directly cause the wear of the parts in the injector. The damage of the injector will cause problems such as unstable engine operation, reduced power, and increased fuel consumption, which will affect the normal operation of the injector. In addition, fuel with too high water content enters the engine, which will reduce its combustion efficiency and cause poor engine acceleration. However, if inferior diesel is added, its sulfur content is high, and it is easy to react with water to generate sulfuric acid during combustion, which gradually corrodes engine parts and reduces the service life of the truck. At the same time, the components of the high pressure common rail system are very expensive. If the electronically controlled injector is damaged, the maintenance cost is quite high. In contrast, the price of the filter is much more moderate, followed by the price, mainly to ensure the integrity of the truck performance, extend the service life of the vehicle, reduce maintenance costs, and save worry and effort.

2023-05-31